FACTORY INTRODUCTION

Overview of factory

Overview of factory Our factory is located in Southeast Industrial Park,the leading economic center of Vietnam, Cu Chi province. The Southeast Industrial Park is not only very convenient for both road and water transport but strategically located between the two most dynamic economic centers in Vietnam, including Ho Chi Ming City with abundant financial resources, science, technology, and high-level labor and Bin Dong province, a leading province in attracting FDIC of the whole country. The Southeast Industrial Park not only has convenient transportation but also borders on the auxiliary industrial areas, which belong to the southern key economic zone.

Our motto is to constantly renovate and improve technology, Nam Do Trading production Joint Stock Company’s Factory has always focused on developing infrastructure and enhancing the quality of human resources. Among the number of emloyees working in the factory, the highly qualifield and experienced employees who mostly have graduated in the mechanical, engineering majors and always receive futher training for skills and workmanship by the company.

In addition, we not only actively learned experiences about how to organize manufacturing from other enterprises but also consulted by Japan’s experts, enhancing the production process to constantly enhance manufacturing efficiency and product quality.

By applying synchronous advanced assembly lines, our factory has reached the designed capacity of 500,000 products per year. Products are brought to consumers through a system of hundreds of distributors nationwide. With the factory’s initial investment of more than 1 million USDA, this is a great success for the company, making a significant contribution to the industrialization and modernization of the country.

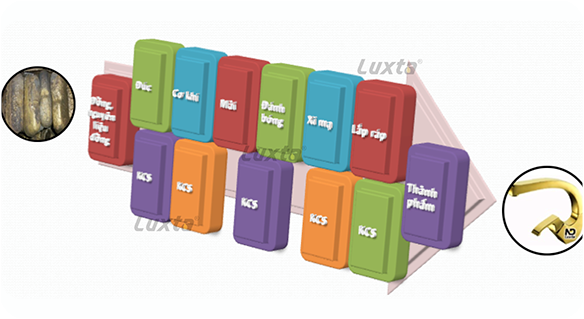

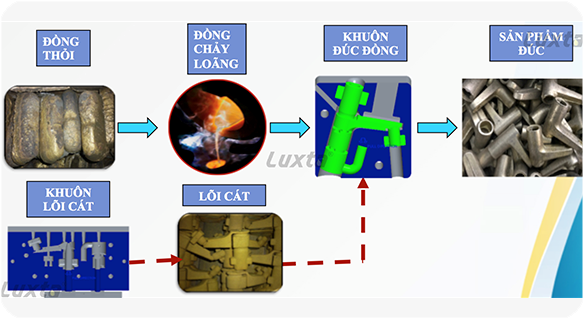

Pictures of the factory and production stages:

Tiếng Việt

Tiếng Việt